Advanced Manufacturing Companies Impacting Pennsylvania

Learn about Keystone State businesses that are impacting their communities and beyond.

Advanced manufacturing reigns in Pennsylvania, as businesses of all types and sizes continue to find success building and expanding in and relocating to the state. And while the Keystone State is home to industry leaders worldwide, many of its companies also have major impacts on their communities and beyond. Read on to learn about three advanced manufacturing companies making a difference in Pennsylvania.

Martin-Baker America Inc. in Johnstown, Pennsylvania

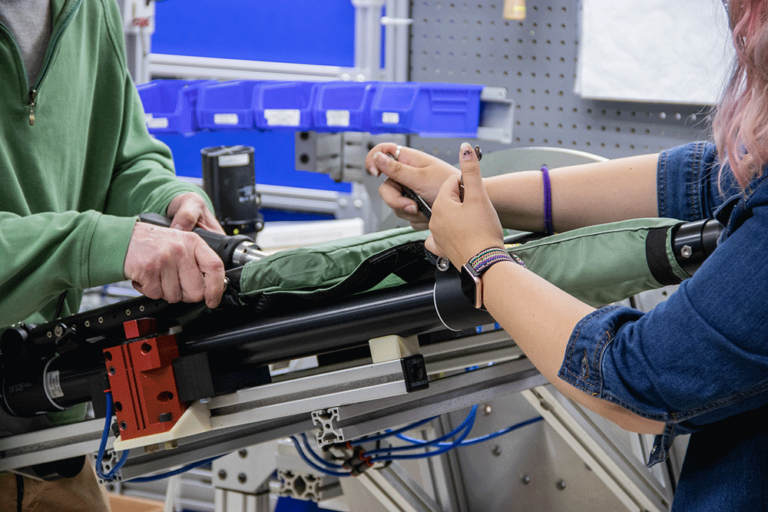

Martin-Baker America Inc. (MBAI) manufactures products that no one really wants to use but that everyone is glad to have when needed – that is, if you are piloting a military aircraft. Located in Johnstown, the company makes components for ejection seats that rocket pilots out of crashing airplanes and parachute them safely to the ground. It also makes components for crashworthy seats that save the lives of military and civilian helicopter crew members during a crash or hard landing.

The company produces ejection components for the F-18, F-35, T-6 and T-38 fixed-wing military aircraft, says Matt Johnson, MBAI’s vice president and general manager. Johnson also notes that MBAI sells these components to its corporate affiliate at the headquarters of Martin Baker Aircraft Co. in the United Kingdom for incorporation into the full ejection seat.

Plus, the company sells components directly to the U.S. government and performs maintenance and overhaul services for seats in use around the world. Since 1949, Martin-Baker ejection seats have saved the lives of more than 7,700 fliers.

MBAI has 160 full-time employees, with 15 of those positioned in military bases across the United States to support active ejection seat field operations. Nearly 20% of the company’s employees are military veterans.

“MBAI benefits a great deal from being in Johnstown. This area has a long history of outstanding work ethic and commitment to military service. We take great pride in being able to support those who serve us. It leads to a strong culture of internal accountability to produce only the finest quality products,” Johnson says.

PackworldUSA in Nazareth, Pennsylvania

Nazareth-based PackworldUSA, which manufactures and distributes medical impulse sealing equipment, was a critical supplier of equipment throughout the pandemic, says Brandon Hoser, PackworldUSA sales manager.

“Our large-format heat-sealing machines were used to manufacture single-use bioprocess bags,” he says. “These are essentially sophisticated drum liners installed into bioreactors where vaccines are produced. The single-use bags are able to be quickly changed out for less downtime between manufacturing lots. The other way, without a single-use bag, is to clean all of the equipment, which is costly and takes time.”

PackworldUSA’s advanced impulse heat-sealing technology accurately controls the temperature applied to heat sealable products.

“When you start looking, heat seals are everywhere, from potato chip bags to blimps. Packworld machines focus on the life science industries, such as pharmaceutical, medical device and bio-tech applications,” Hoser says. “Most of these applications are creating sterile barrier systems, which maintain the sterility of devices and pharmaceuticals to mitigate infection or contamination. Our technology helps save lives and also can keep your snack food fresh.”

East Penn Manufacturing in Lyons, Pennsylvania

Family-owned East Penn Manufacturing operates the world’s largest single-site lead battery manufacturing facility in Berks County. Founded 77 years ago by DeLight Breidegam Jr. and his father, DeLight Sr., the company is Berks County’s largest employer and has more than 10,300 employees in 34 states and five countries.

“When the late DeLight Jr. was asked, ‘Why stay in Berks County?’ he would offer remarks about the quality of the workforce and their remarkable work ethic in support of the company’s customers,” says Joel Brady, assistant vice president of marketing.

The company prioritizes creating developmental opportunities for the community.

“Our English as a Second Language Program is the first on-the-job learning opportunity in Berks County,” he says. “This has provided English language training to those in our community and has opened new doors to a steady career and opportunities for advancement by overcoming language barriers.

East Penn’s Advanced Manufacturing Technologies Scholarship Program pays for an associate degree in the growing field of advanced manufacturing technology. Students learn technical roles within these production activities that can include working with information, automation, computation, software, sensing and networking. Those are skills that lead to well-paying jobs within the company and give people the opportunity to avoid college debt, Brady says.

“Our culture emphasizes the importance of family. In fact, family is one of our cultural values. We have generations of families who are currently working here at East Penn or who have worked here previously. This creates a strong sense of commitment to the company and to safely producing quality products for our customers,” Brady says.

This article was sponsored by the Pennsylvania Department of Community and Economic Development.