5 Manchester, NH, Companies Leading the Way in Biotechnology

From 3-D printed organs to an all-terrain mobility device, some of the country’s most exciting healthcare advances are happening in Manchester.

Imagine if, instead of finding and waiting for a donor match, transplant patients could receive a customized 3-D printed lung. Or what if chronic kidney diseases could be treated using a patient’s own cells?

In Manchester, New Hampshire, maverick inventors, as well as talented engineers, scientists and manufacturers, are solving some of the world’s most complex medical problems. As a result, the region has become a pioneer in a growing field known as biofabrication, which uses manufactured cells, tissues and organs to cure chronic disease and treat traumatic injuries while lowering the cost of health care. Not only is this niche field giving way to life-changing medical solutions, but it’s also creating thousands of jobs in the region.

While Manchester organizations are manufacturing cells, tissues, and organs today, the city has a rich history of pushing boundaries with inventions that include artificial kidneys, personal mobility devices, and much more.

These five Manchester enterprises are making their mark on biotechnology and the medical world.

In This Article

United Therapeutics

Once a hub for textile manufacturing, the riverfront Manchester Millyards today is a thriving biotechnology industry hive, a reputation that’s solidified even further as United Therapeutics takes over a space in the historic district to manufacture its intricate 3-D printed organs.

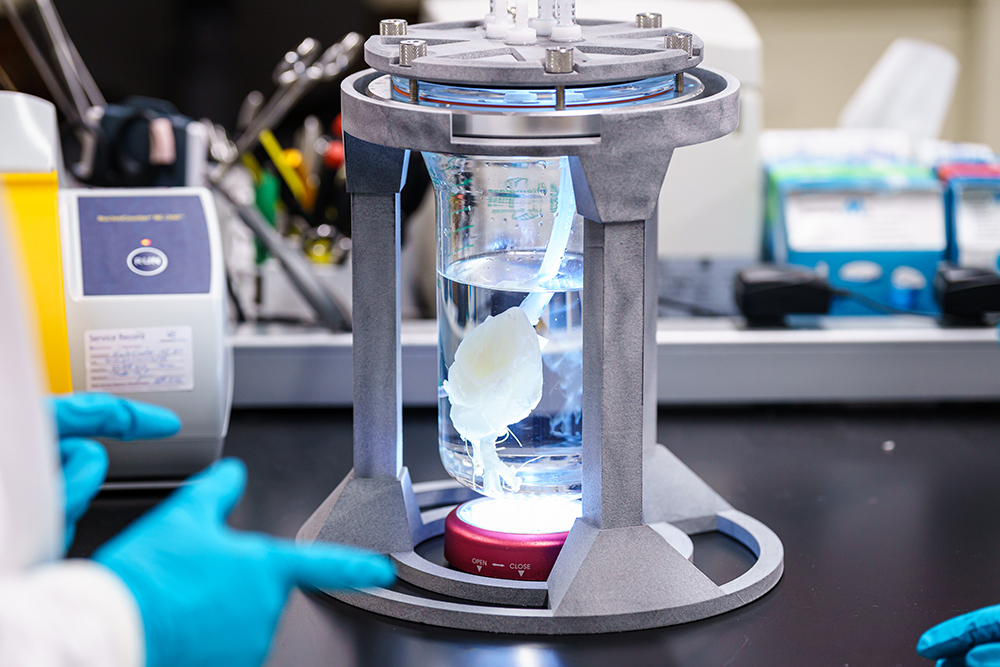

While more than 2,500 people in the United States received a lung transplant in 2021, there were still 1,075 patients on a waiting list, according to the U.S. Health Resources and Services Administration. To help address this need in the future, United Therapeutics has created 3-D printed human lung scaffolds with a goal of manufacturing an unlimited supply of transplantable lungs in the future.

The public benefits company hopes to have these personalized, manufactured lungs cleared for trial within the next five years, says Dr. Martine Rothblatt, the chief executive officer and chairperson for United Therapeutics. Already, scientists and engineers are working together to print lung scaffolds “as accurately as driving across the United States and not deviating from a course by more than the width of a human hair,” Rothblatt says.

Advanced Regenerative Manufacturing Institute

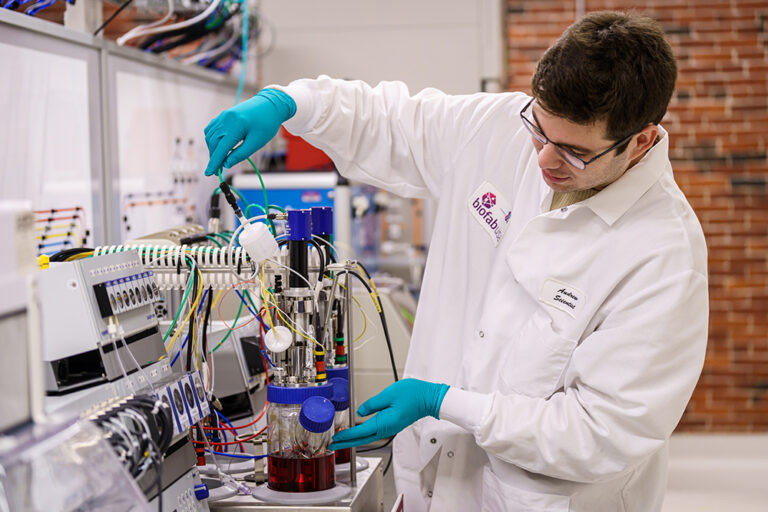

Five years ago, with an $80 million grant from the Department of Defense, the Advanced Regenerative Manufacturing Institute (ARMI) launched BioFabUSA, which is a public-private partnership with more than 170 members that includes companies, academic institutions and nonprofit organizations.

Ever since the biofabrication field has been gaining significant momentum, with a major boost in September as Manchester won a $44 million federal “Build Back Better” grant for its biofabrication cluster. Coalition and industry partners are kicking in an extra $12.5 million, and the funds will not only revolutionize health care but also create thousands of high-paying jobs as well as workforce training opportunities, according to Manchester Mayor Joyce Craig.

The “Build Back Better” grant funds will be used to support four key projects. First, a “Startup Lab” will help entrepreneurs establish the companies that will define this new industry. A manufacturing facility will meets the specific needs of cell, tissue, and organ production for clinical trials and commercial products. A certificate and apprenticeship program will prepare workers to apply their skills to this new industry. Finally, a Vertiport will be created at the Manchester Armory for aerial transportation of these products to regional clinical sites via electrical take-off and landing (eVTOL) planes.

DEKA Research and Development

At DEKA Research and Development, the iconic technology skunkworks led by inventor and entrepreneur Dean Kamen, no idea is too big. So the engineers, technicians, machinists, designers, and other world-changers at DEKA are encouraged to let their creativity fly.

Kamen, who had previously invented the world’s first wearable insulin pumps for diabetics, founded DEKA in the Millyard in 1982. Since then, DEKA has been working with major pharmaceutical and medical device companies to develop products that redefine the state-of-the-art in healthcare. DEKA’s impressive roster of inventions includes home dialysis equipment (an artificial kidney), a coronary artery stent, [a wearable drug delivery pump used to treat lung disease,] the LUKE prosthetic arm, and the iBOT personal mobility device (more on this below).

Microsoft founder Bill Gates said that DEKA is “a cross between the Willy Wonka Chocolate Factory and Edison’s labs.” Most of DEKA’s products are life-changing for patients that need them, but a few fun products were designed for all to enjoy. DEKA is best known as the birthplace of the Segway. Still, most people don’t know that the Coca-Cola Freestyle (a revolutionary soda fountain that pours 125+ flavors) was also developed by DEKA. Among DEKA’s 6,000+ patents, the “controllable launcher for launching human payloads” looks like a blast!

Mobius Mobility

The iBOT personal mobility device is not your grandfather’s wheelchair. Unlike standard wheelchairs, it happily navigates grass, sand, snow, and curbs. Amazingly, it will even climb stairs. The iBOT is designed for people who want to move around the world without limitations.

One of the most valuable features of the iBOT is its ability to balance on two wheels (like a Segway) and bring users eye-to-eye with family, friends, and colleagues. iBOT user Gary Linfoot says, “When you go out to a social setting, back up at six feet, talking to somebody eye-to-eye, you get this sense of dignity. The disability just kind of fades into the background.”

The iBOT is manufactured in the Manchester Millyard, and many new users are first trained to use their devices at Mobius’s headquarters here, as well. During COVID, team members from Mobius traveled to 25 Department of Veterans Affairs (VA) locations around the country that specialize in spinal cord injuries; Mobius donated 50 iBOTs and showed VA staff how best to leverage this life-changing device for veterans.

Advanced Solutions Life Sciences

For nearly 40 years, Advanced Solutions has provided technologies to address numerous challenging needs around the world. Today, the unique team of engineers and life scientists at Advanced Solutions Life Sciences, with laboratories located in the historic Manchester Millyard, is leading the way to revolutionize the future of healthcare by combining hardware and software with 3D Biology. These advanced solutions enable scientists, engineers, technologists and medical professionals to develop and manufacture human organs, tissues, prosthetics and more.

At the heart of the technology solutions is the BioAssemblyBot® (#WeCallHerBAB), a robot that, along with interchangeable hands, mimics the capabilities of the human arm in building, assembling, and manufacturing living structures and therapeutic tissues. BAB and other ASLS biotechnologies, such as the Angiomics® tissue vascularization platform, are being used around the globe to produce on-demand, customized healthcare solutions such as personalized human hearts, person-specific replacement bone grafts for use in tissue reconstruction or produce custom-fit breast prosthetics to empower self-confidence in breast cancer survivors.

This article was sponsored by Manchester Economic Development Office.