Pennsylvania Apprentices Power the Future

Thanks to public and private apprenticeships, career opportunities abound in advanced manufacturing.

Just as molding and forming are part of the process of manufacturing plastics, the plastics industry itself is now shaping the opportunities available for the emerging workforce in Pennsylvania.

A cornerstone of the state’s economy, the plastics industry – along with subsidiary industries – accounts for more than 1.7 million jobs.

Helping to keep talent flowing to this booming industry are public and privately funded apprenticeship programs that train the next generation of workers as the current workforce begins to retire.

And those programs are vigorously supported by the state. In fact, the Pennsylvania Department of Labor & Industry Apprenticeship Training Office supported 873 program sponsors and 1,596 occupation-specific registered apprenticeship programs across the commonwealth, with 16,654 registered apprentices currently active.

And programs like the Pennsylvania Department of Community and Economic Development’s (DCED’s) Pre-Apprenticeship and Apprenticeship Grant Program ensure that, from classroom expenses to on-the-job training, apprenticeship programs in the plastics sector – and so many other advanced manufacturing sectors – have the support they need to fuel the workforce.

Money Matters

For example, with funding from DCED’s grant program, Pennsylvania College of Technology in Williamsport plans to train around 160 advanced manufacturing apprentices over the next three years. The college offers eight fully developed apprenticeship programs in some of the state’s highest-demand fields, including industrial manufacturing and plastics process technology. The college also sponsors a pre-apprenticeship program for high school students.

“This grant allows us to continue delivering that program to the 22 schools and cyber schools across the commonwealth that have already participated, while potentially expanding it to more school districts. The funding also allows us to reduce the cost to employers for our registered apprenticeship programs, helping them meet the massive skills-gap challenges they continue to face,” says Beth Bittenbender, executive director of operations and special projects for workforce development at the Pennsylvania College of Technology.

The college has been the recent recipient of several benefactors – both public and private – including global powerhouse Lockheed Martin, which in 2021 awarded scholarships to nine Pennsylvania College of Technology students. The scholarships were established to help offset costs toward earning an associate degree or certification in high-demand, technical fields, including advanced manufacturing.

“We were the second-highest awarded school with nine recipients, so that shows Lockheed very much values the degree programs at Penn College,” says Elizabeth Biddle, senior corporate relations director for the Pennsylvania College of Technology.

“This is such a great opportunity for our students. When the application process begins, we get it out in front of as many students as we can and encourage them to apply because a lot of associate degrees in the School of Engineering Technology meet the criteria.”

Powerful Partnerships

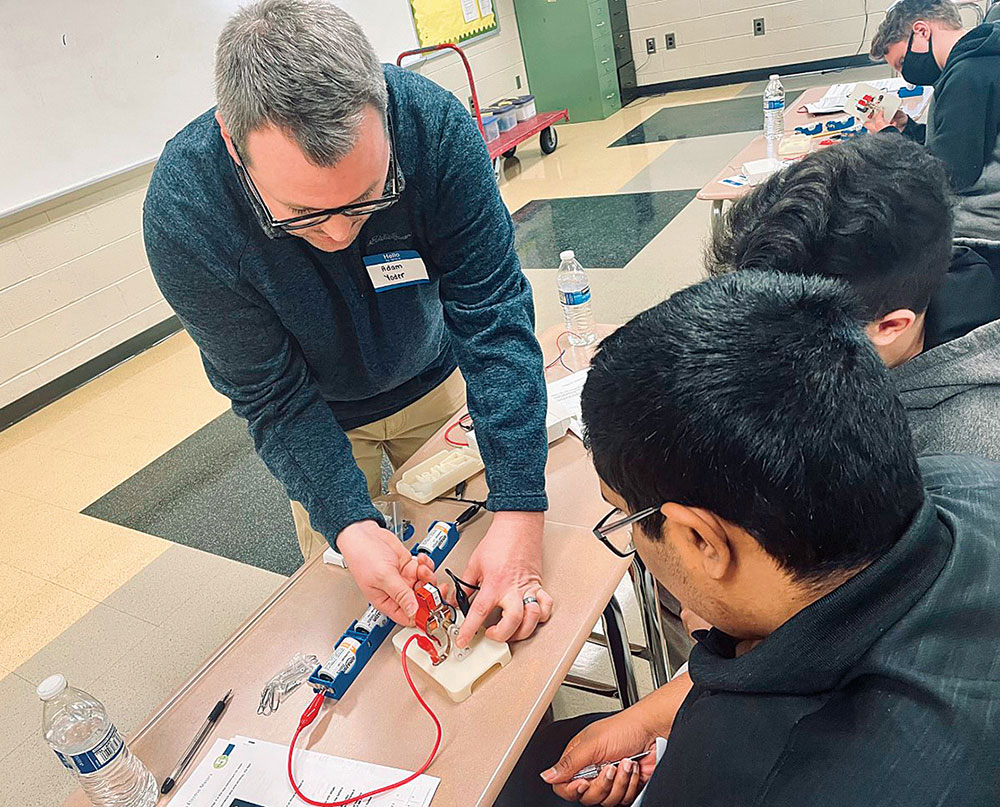

A Plastics Process Technician Apprenticeship Program, created in partnership with the American Injection Molding (AIM) Institute and Keystone Community Education Council, also works to provide post-secondary learning opportunities for Commonwealth University of Pennsylvania students in the advanced manufacturing field.

As a new joint endeavor between Bloomsburg, Lock Haven and Mansfield universities, Commonwealth University aims to rethink higher education through a model that’s more practical, personalized and affordable. Its two-year program offers nearly 350 hours of classroom training at the AIM Institute and 4,000 hours of paid, hands-on training at a partner company.

“The Plastics Process Technician Apprenticeship is helping to narrow the skills gap that injection molding companies need and helping to retain their institutional knowledge in preparation for a retiring workforce,” says Hope Lineman, strategic advisor to the chancellor for workforce innovation at Pennsylvania’s State System of Higher Education.

“Apprentices gain hands-on experience, expand their skill set, and learn from their peers and colleagues on a daily basis. Apprenticeships offer a much higher level of support than regular jobs, and apprentices are able to better understand the implementation of the topics they learn in the classroom. The ability to learn and work at the same time gives them a deeper understanding of new processes and how to troubleshoot.”

Lineman says the partner companies also benefit because it allows them to train their workforce to meet their specific needs.

“Apprenticeship programs help employers recruit and develop a highly skilled workforce that helps grow their business,” she says. “Employees appreciate companies who invest in their professional development as do apprentices. That loyalty increases productivity, reduces costs associated with turnover and leads to long-term financial benefits to the business.”

Education, Careers & Opportunity

Robotics Revolutionize Agriculture in Pennsylvania

Two industries come together to produce game-changing solutions for the future.

Q&A with Pennsylvania Industry Leaders

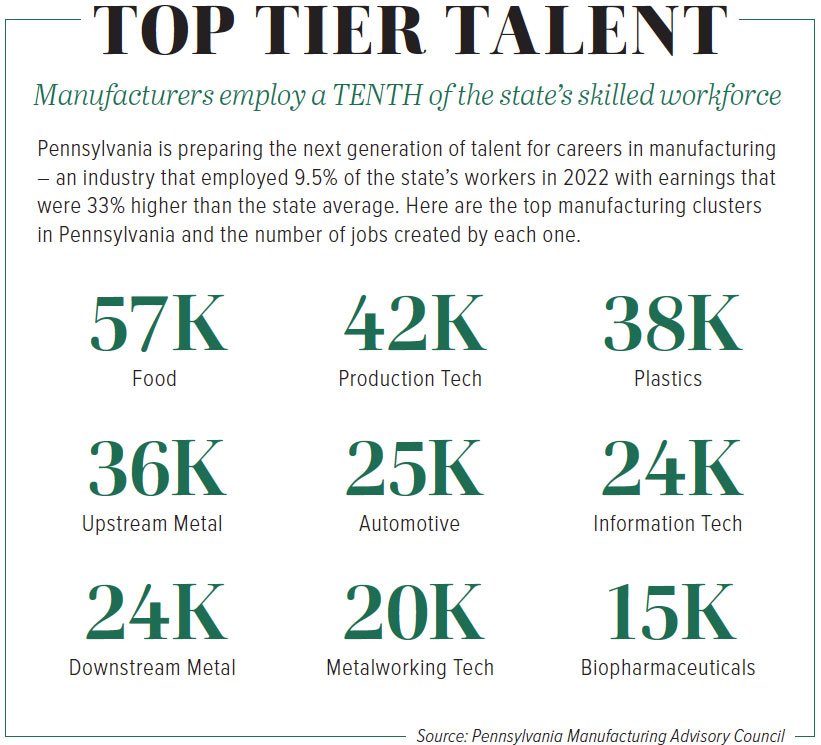

The Pennsylvania Manufacturing Advisory Council is a public-private work group focused on keeping Pennsylvania manufacturing competitive. One of the ways it does that is by creating a unified voice for manufacturers, telling the story of the state’s manufacturing sector – where it is and where it is going.

Co-chairs Eric Esoda, president and CEO of the Northeastern Pennsylvania Industrial Resource Center (NEPIRC), and Dan Fogarty, director of workforce development and COO at Berks County Workforce Development Board, share insights about the state’s manufacturing industry strengths and workforce.

Eric Esoda

What insights have manufacturers shared with you about doing business in Pennsylvania?

Industry leaders we speak to favorably comment upon the combination of Pennsylvania’s proximity to major markets, lower cost of living and high livability factor, which includes features such as the abundance of outdoor recreation options, the ease of travel, the availability of quality education, the family-orientation of our communities and the abundance of regional traditions that celebrate the arts, varying cultures and overall diversity of our commonwealth.

In Pennsylvania, our manufacturers feel as if they are part of the community landscape and part of the fabric of the neighborhood. They feel welcome, appreciated and valued. Their relationships within their communities result in lower turnover, more multi-generational workers, easier talent attraction and more overall support when they expand and grow.

Dan Fogarty

How is Pennsylvania attracting a new generation of manufacturing workers?

We’re focused on getting our younger generation more informed, involved and engaged in exploring manufacturing careers early on. Programs such as the statewide “What’s So Cool About Manufacturing?” student video competition, “Explore the New Manufacturing” in Western Pennsylvania, “Manufacturing Ambassador Dream Teams” found throughout the eastern half of Pennsylvania and others currently get thousands of middle school, high school and community college students excited about manufacturing career options each year. When coupled with Educator in the Workplace, Manufacturing Apprenticeships, Manufacturing Fellows and other internship and student engagement programs concurrently operating across Pennsylvania, the future of our manufacturing economy is looking particularly bright from a workforce availability vantage point.

Pennsylvania is proving that “this isn’t your grandfather’s manufacturing” and that there’s a place for everyone in tomorrow’s high-tech manufacturing sector.

Get to Know Pennsylvania

Want to learn more about living and working in Pennsylvania? Check out the latest edition of Livability Pennsylvania: Work Smart. Live Happy.