Bright Future Ahead for Manufacturing in Ames

An Iowa initiative teams educators with manufacturers to transform how local goods are made and distributed.

A statewide initiative to boost manufacturing competitiveness in Iowa will help companies in the Ames MSA.

The Manufacturing 4.0 Workforce Innovation initiative, a statewide program led by the Iowa Economic Development Authority, provides a multimillion-dollar series of grants aimed at helping smaller manufacturers and supporting adoption and integration of smart technologies.

Meet the Fourth Industrial Revolution

The program was named for the fourth industrial revolution – the first three being the advents of steam power, the assembly line and basic automation.

“Our job is to make industry in Iowa better, and we do that in a lot of different ways,” says Mike O’Donnell, manufacturing program director at Iowa State University’s Center for Industrial Research and Service (CIRAS), which played a key role in helping manufacturers adopt cutting-edge technology.

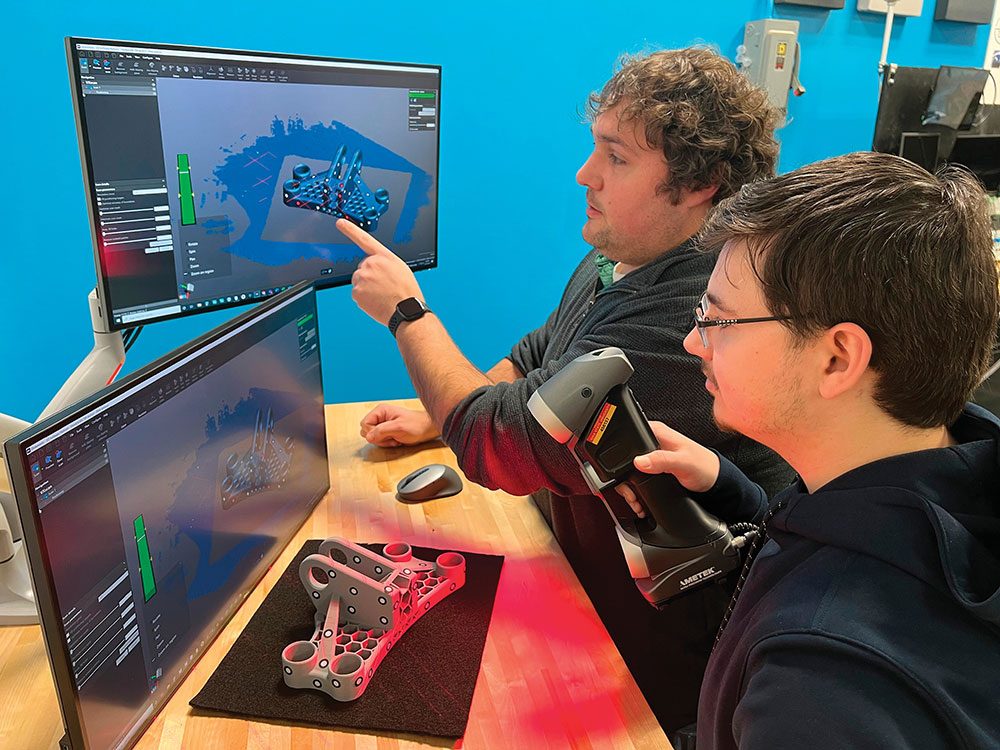

The university’s valuable network of equipment and infrastructure, supporting like-minded causes, can also be found at several facilities around campus, including the Virtual Reality Applications Center (VRAC), an interdisciplinary research center focused at the intersection of humans and technology.

Manufacturing simulation is one of the fields that benefits from the center’s innovative solutions, and ISU students and staff have even made strides developing an online educational software that teaches manufacturing classes through VR. Major manufacturers, such as John Deere, have supported virtual research at VRAC.

“A lot of focus is on manufacturing, since it’s the No. 1 industry in the state and employs more than 220,000 people,” O’Donnell says.

“The fourth industrial revolution, what we’re seeing now around the globe, is the complete physical and digital integration of manufacturing. There is a huge change in the way people make things, and we want to help all our manufacturers survive and thrive through this change.”

Mike O’Donnell, CIRAS

The Manufacturing 4.0 Workforce Innovation program had several major themes, one of which was increasing successful technology adoption, especially for smaller companies.

“If they bet on an expensive piece of tech and it doesn’t go well, they’re in trouble,” O’Donnell says. “A bigger business has some space to learn; smaller ones don’t have leeway. We at CIRAS went out, performed assessments of the whole business, then sat down to review where they had the opportunity to implement new technologies, as well as some things to think about, and some areas of caution.”

Companies then took that information and used it as a springboard to apply for one of the initiative’s grants. And apply they did.

O’Donnell says CIRAS had hoped to perform between 30 and 50 assessments, for 25 or so companies. Instead, the team completed 230 assessments – 150 in the initiative’s first three months alone.

“There was interest from companies of all shapes and sizes, whether they were making food or electronics, cutting metal or molding plastic,” he says.

Manufacturing Solar Power

One company that benefited from Manufacturing 4.0 was PowerFilm Inc., a solar-technology manufacturer based in Ames. The company was able to implement a new process with the tools and advice it obtained through the process – a line of business that helps it compete more successfully against overseas providers, says Dan Stieler, company president.

“We’ve been around 30 years, putting a thin film with interconnected solar cells onto robust, lightweight plastic that can be used as foldable panels for the military, rollable panels for permanent outdoor applications and others that are customized to specific requirements,” Stieler says.

In 2018, the company added another process to make cells for the refrigerated-trucking industry, allowing solar power to back up diesel-run refrigerated units.

“That’s been amazing for them,” Stieler says. “They can keep their batteries charged up without as big a load on their alternators and save fuel.”

The PowerFilm team used its Manufacturing 4.0 funding to increase its automation capabilities, which boosted production capacity and lowered labor costs. The result is more inventory and the ability to charge less for it, both of which are huge differentiators.

“We’re one of the only U.S. solar manufacturers that’s really left that’s been around for a long time,” he says. “We moved from zero volume for these new panels in 2018 to around 15,000 panels a year. Now, with the new upgrades, we can look at 6,000 or more panels per week. The initiative was very well timed, and it’s been very exciting for us.”

Manufacturing Success Stories

Some of the big-name manufacturers with production facilities in the region include 3M Company, Barilla America, BASF, Danfoss and John Deere, and more companies are launching operations all the time.

That includes Dutch manufacturer Berdex, who in 2022 chose Ames for its U.S. headquarters to build livestock trailers. Berdex located in Ames inside a vacant facility formerly occupied by Caremoli and brought about 20 new jobs to the community.

Several other smaller manufacturers are enjoying success in the region, including companies like Ag Leader Technology, Amcor Rigid Packaging, DSM Nutritional Products, Interpower Corporation, Trelleborg Sealing Solutions, Vermeer and WG Provisions. Another success story is Hach Company, which manufactures and distributes analytical instruments for testing the quality of water and other liquid solutions.

There is also a community of small, family-owned manufacturers in the region, and while they have a strong presence in this area, their impact is felt far beyond. One of those companies is Sukup Manufacturing, which has a production site in Sheffield and an office at Iowa State University’s Research Park.

Sukup Manufacturing is the world’s largest family-owned and operated manufacturer of grain storage, drying and handling equipment, and it also constructs steel buildings. Nearly 30% of the company’s full-time employees have been with Sukup for more than 10 years.

Another family-owned manufacturing company is Dose Steelworks, which is based in Bouton. The company was started nearly 20 years ago by Brett Dose as a small repair shop for farm equipment and to weld broken machinery back together, and it has evolved into a manufacturing business that now employs 25 people.

The company primarily builds Headhunter Trailers that are sold throughout the U.S. and internationally to serve farmers for a variety of hauling needs.

“My wife (Andrea) and I are both from rural small-town Iowa, and we wanted to establish the company in a smaller community and provide good jobs,” Dose says. “We looked at other places, and Story County just felt like home to us.”

And you can’t argue with the company’s success. Dose says his business has gone from ordering two to three pieces of steel at a time to ordering truckloads of steel. The company has also expanded its plant, recently going from a 30,000-square-foot facility to its current 130,000-square-foot building.

“Within a couple of years, we’ll probably be adding to our current building and doing more hiring,” he says. “We’re kind of living the American dream here in Story County, manufacturing and shipping high-quality trailers all over the 48 continental states and beyond.”

Get to Know Ames

Want to learn more about living and working in Ames, Iowa? Check out the latest edition of Livability Ames, Iowa And the Greater Boone & Story County Region.